2. Continuity

Continuity is about ensuring and extending the battery life

of the device. Battery life is one of the most important considerations for IoT

devices. Long battery life is a huge competitive advantage in consumer IoT

devices. For industrial IoT devices, a battery life of five or ten years is the

common expectation. For medical devices, such as pacemakers, device life can

mean the difference between life and death. Battery failure is not an option.

To meet this long battery life requirement, the integrated

circuit (IC) designers need to design ICs with deep sleep modes that consume

very little current, reduce the clock speed and instruction sets, as well as

implement low battery voltages. From a wireless communication perspective,

standard groups are also defining new low power consumption operating modes

such as NB-IoT, LTE-M, LoRa, Sigfox that offer limited active operation time

while maintaining low power consumption. Product designers who integrate

sensing, processing, control and communication components into the final

product, must know how the peripherals behave and consume power, and optimize

the product’s firmware and software to simplify operation and reduce power

consumption. All these activities require capable measurement tools that can

offer deep insights into the device current consumption behaviors.

3. Compliance

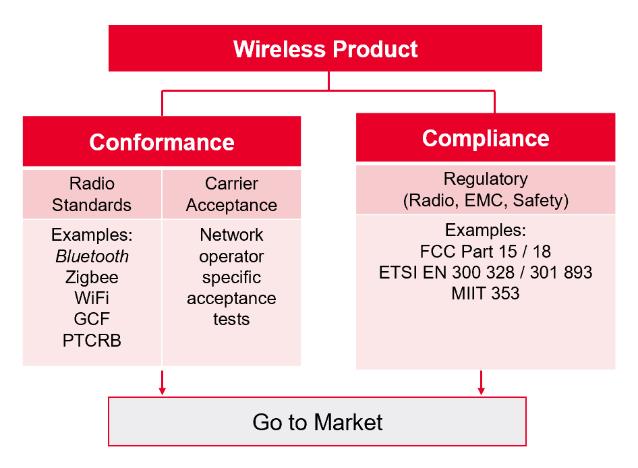

Compliance is about making sure your IoT devices adhere to the radio standards and global regulatory requirements before gaining market entry. There are two main categories of compliance tests: radio standards conformance and carrier acceptance tests, and regulatory compliance tests such as RF, EMC, and SAR tests. Design engineers often scramble to meet the tight product introduction timeline and ensure smooth global market penetration while complying to the latest regulations. Frequent updates to the regulations also further add to the complexity. Figure 3 shows the examples of conformance and compliance testing requirements.

Figure 3: Conformance

and compliance testing requirements of IoT devices.

To reduce the risk of failure during compliance testing and

to keep to the product release schedule, designers can consider investing in

inhouse pre-compliance test solutions so that testing can be carried out at every

stage of design to fix issues early in the design phase. Choosing a

pre-compliance test system that is adapted from the compliance test system from

the test lab can also help to ensure measurement correlation and reduce risk of

failures. Compliance testing is complex and time-consuming. It can take up to

days or weeks to complete if performed manually. Choosing an automated test

system can help to save test time and allow faster time-to-market.

4. Coexistence

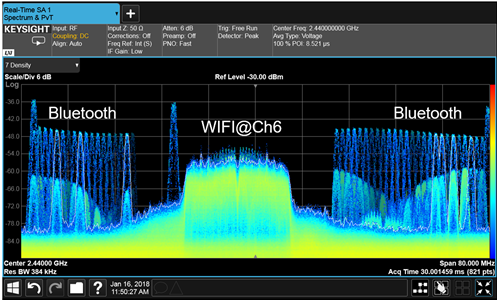

Coexistence is about the ability of the wireless device to operate reliably in the presence of other interfering signals. With billions of devices released to the market, congestion in the radio channels is a problem that will only get worse each day. To address wireless congestion, standard bodies have developed test methodologies to evaluate device operations in the presence of other signals. For instance, in Bluetooth®, adaptive frequency hopping (AFH) lets a Bluetooth device drop channels that experience high data collisions (figure 4). There are also other collision avoidance techniques such as listen before talk (LBT) and cooperative collision avoidance (CCA) to improve transmission effectiveness. The effectiveness in a mixed signal environment is unknown. When the radio formats don’t detect each other, collisions and data lost will happen.

Figure 4: Bluetooth

device bypasses the WiFi channel 6 to avoid interference with the WiFi signal.

For consumer applications, delays or pauses in wireless

headsets or wearables are annoying, but acceptable. An industrial sensor that

loses the control signal, or an infusion pump that stops working due to

surrounding interference signal can have dire consequences. Therefore, it is

crucial to perform coexistence testing to measure and assess how your device

will operate in a crowded and mixed signal environment. IEEE provides some

guidance in ANSI C63.27 (American National Standard for Evaluation of Wireless

Coexistence) regarding key considerations for coexistence testing that includes

evaluation processes, test setups and risk-based testing tiers. Device

manufacturers are highly recommended to assess the potential risk to maintain the

device’s functional wireless performance in the presence of unintended signals

found in the same operating environment.

5. Cybersecurity

With increasing deployment of IoT in mission-critical

applications, the need for cybersecurity protection is becoming even more

important. While cyberattacks can happen at many layers – from the device level

to the communication network, cloud or applications, most of the traditional

security protection tools have focused on securing the network and cloud. The

endpoint and over-the-air vulnerabilities are frequently overlooked. Formats

like Bluetooth and WLAN are matured technologies and are commonly used

in many applications. However, little has been done to address the over-the-air

vulnerabilities. The complexity of these wireless protocols translates into

potential unknown pitfalls in the device radio implementations that allow

hackers to access or take control the device.

According to IDC, 70% of security breaches originate from

endpoints[1].

Extra care should be taken to safeguard these IoT devices. Over-the-air

vulnerabilities and potential point of entries into the IoT devices should be

identified. The device should be tested using a database of known over-the-air

threats/attacks to monitor the device response and to detect anomalies. The

database must be regularly updated to safeguard the device from the latest threats.

Building A Strong Foundation Through the 5Cs of IoT opens doors to exciting new applications and opportunities for many industries. But it also brings unprecedented challenges that require thinking in new ways to meet the mission-critical requirements. Delivering successful IoT implementation requires designers and engineers to overcome the technical challenges in the 5Cs of IoT. Having a deep understanding of these technical challenges and knowing what the key design and test considerations will build a strong foundation for implementation and deployment across the IoT ecosystem. The right design, validation, compliance testing and manufacturing tools throughout the product lifecycle will help to ensure that the IoT delivers on its promises.

The author is Sook Hua Wong, Industry Segment manager general electronics measurement solutions at Keysight Technologies, Inc.

About the author

Sook Hua is

an Industry Segment Manager with Keysight Technologies residing in Penang,

Malaysia. She is the strategic solution planner responsible for Keysight

Internet-of-things (IoT) solution portfolio expansion and marketing program

planning to drive growth in the general electronic segment of Keysight

Technologies.

Prior to

this role, she was the product planner responsible for strategic planning and

product portfolio development for the RF/Microwave power meter and sensor.

She received her Bachelor Degree of Electrical Engineering from University of Technologies Malaysia (1999) and Masters of Science Degree in Electronic System Design Engineering from University of Science Malaysia (2003). She has spent 20 years at Keysight Technologies with the last 15 years in the General Electronics Measurement Solution (GEMS) team under various roles, including manufacturing, product development, sales support, product marketing, and a product planner.

Comment on this article below or via Twitter: @IoTNow_OR @jcIoTnow

Leave a Reply