As a business owner, you likely evaluate your employees’ performance from time to time. But, your employees aren’t the only ones you should be assessing. If you have suppliers you go to for inventory and materials, you need to evaluate their performance, too. To learn more about supplier evaluation and how to evaluate a supplier, read on.

Supplier evaluation process 101

Suppliers and vendors can make or break your company’s success. With good suppliers and vendors, you can streamline business operations, lower risks, and eliminate unnecessary expenses. Not to mention, conducting regular evaluations can help you spot problems and create a more prosperous partnership.

While evaluating your suppliers, consider the following:

- Performance

- Quality

- Production capacity

- Risk

- Cost

- Delivery

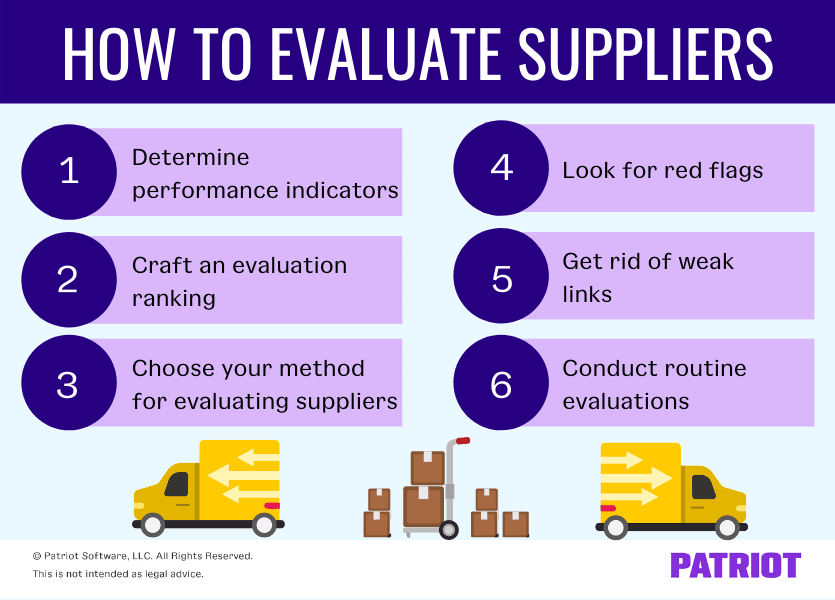

So, what all should a supplier assessment include? Before you can start evaluating suppliers, you need to have a game plan. To get started learning how to evaluate suppliers, follow these six steps.

1. Determine performance indicators

To evaluate your suppliers’ performance, you need to determine what you’re going to be rating them on. The metrics you use can vary depending on your type of business and the suppliers you have.

Here are a few examples of performance indicators for vendors:

- On-time performance percentage

- Delivery track record

- Price competitiveness

- Lead time

- Defect rate

- Purchase order and invoice accuracy

- Vendor availability

Again, your performance indicators may vary depending on your business and the supplier. Narrow down what indicators your business will look at when it evaluates suppliers.

2. Craft an evaluation ranking

If your business has a lot of suppliers, it may be easier to evaluate them if you break them down by classification.

For example, you may want to classify suppliers into various categories, such as Level 1, Level 2, and Level 3. The categories allow you to evaluate suppliers using different surveys or methods.

Typically, companies use this step to classify suppliers based on how critical they are to the business.

3. Choose your method for evaluating suppliers

There are a number of supplier evaluation methods to choose from. You may want to use:

- Evaluation forms

- Surveys

- System metrics

- Software

Regardless of which method you choose, it’s always good to get feedback from your team. With forms and surveys, you can have employees answer questions about suppliers and vendors and receive honest feedback.

In conjunction with employee feedback, you may also want to gather metrics (e.g., number of products you had to return) to back up claims, especially if the supplier needs to make improvements.

You may want to meet as a team to discuss supplier performance. Or, you may designate a person or small group to go over the feedback and metrics.

4. Look for red flags

There’s nothing worse than dealing with a supplier who performs poorly and doesn’t meet expectations. When going through your evaluations, be on the lookout for supplier red flags. Red flags can include:

- Poor quality products

- Bad business-supplier relationships

- Overpriced products or services

- Poor communication

If you notice some red flags, don’t jump the gun and dissolve the partnership right away. Instead, offer constructive feedback. Discuss your concerns with suppliers who are giving you warning signs. Talk through your problems and use your data to back up your feedback. Consider giving them a warning first before jumping to more drastic actions (e.g., firing your supplier).

5. Get rid of weak links, if necessary

Sometimes, an issue (especially a repetitive one) with a supplier may be the final straw. And in some cases, it may be best to cut ties with an unreliable and underperforming supplier.

If you have discussed performance problems with a supplier and they have not improved, it may be time to end your business relationship with them.

If you have decided to let go of a supplier or vendor, let them know as soon as possible. Communicate with your supplier why you want to cut ties and let them know you would like to end the business relationship.

6. Conduct routine evaluations

Of course, your supplier evaluations shouldn’t occur just once in a blue moon. You should conduct assessments on a regular basis to ensure your business is getting good quality products, minimizing operating costs, and streamlining production timelines.

Conduct routine evaluations regularly, like once a month, quarter, or year. Make sure to inform your team and suppliers about your business’s evaluation schedule so they can prepare.

Need a way to record transactions, like payments made to suppliers and vendors? Give Patriot’s affordable and easy-to-use accounting software a go. With Patriot’s online accounting, you can streamline your books and get back to business. Try it for free today!

This is not intended as legal advice; for more information, please click here.

Leave a Reply